Shrink Wrap Solutions for Construction

Protect. Contain. Accelerate.

When construction projects are threatened by weather delays, dust hazards, or exposure to sensitive equipment and materials, shrink wrap containment provides a reliable, high-performance solution to keep your site protected, clean, and on schedule.

Shrink wrap systems create durable, weather-tight enclosures that outperform traditional tarps and temporary coverings—allowing work to continue safely and efficiently in challenging conditions.

Why Use Shrink Wrap in Construction?

Weatherproof Your Worksite

Shrink wrap creates a fully sealed barrier that protects against rain, wind, snow, and moisture. By eliminating weather-related delays, crews can continue working year-round with confidence.

Contain Dust, Debris & Hazards

Heat-welded seams form an airtight enclosure that contains dust, debris, and hazardous materials—protecting workers, building occupants, and surrounding environments.

Create Clean, Controlled Environments

Shrink wrap is ideal for sensitive operations such as painting, sandblasting, curing, abrasive blasting, and hazardous material remediation. The sealed environment improves work quality while maintaining compliance with safety standards.

Protect Equipment & Materials

Valuable tools, machinery, and prefabricated components are shielded from weather, contamination, and damage during construction, storage, or transport.

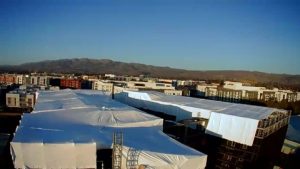

Safe Scaffold & Façade Enclosures

Wrapping scaffolding and building façades helps prevent falling debris, reduce noise, and improve overall site appearance—while enhancing worker safety and site control.

Common Applications

Shrink wrap containment is commonly used for:

Building Renovations & Façade Restoration

Roofing and Exterior Envelope Projects

Hospital, Healthcare & School Remodels

Bridge, Tunnel & Infrastructure Repairs

Modular Construction & Equipment Shipping

Shrink Wrap vs. Traditional Coverings

Compared to tarps or plastic sheeting, shrink wrap offers clear advantages:

Fully sealed, heat-welded seams that block moisture and contaminants

Exceptional durability to withstand high winds and heavy rain

Clean, professional appearance with no flapping or tearing

Allows work to continue in adverse weather conditions

Improves job-site safety, cleanliness, and efficiency